Pre-Engineered Metal Buildings: The Future of Construction

Pre-engineered metal buildings (PEMBs) are transforming the construction industry with their cost efficiency, durability, and versatility. These structures are designed and manufactured off-site, making them an ideal choice for a wide range of applications, from warehouses to commercial spaces.

In this article, we’ll explore the benefits, applications, and essential considerations when opting for a pre-engineered metal building.

What Are Pre-Engineered Metal Buildings?

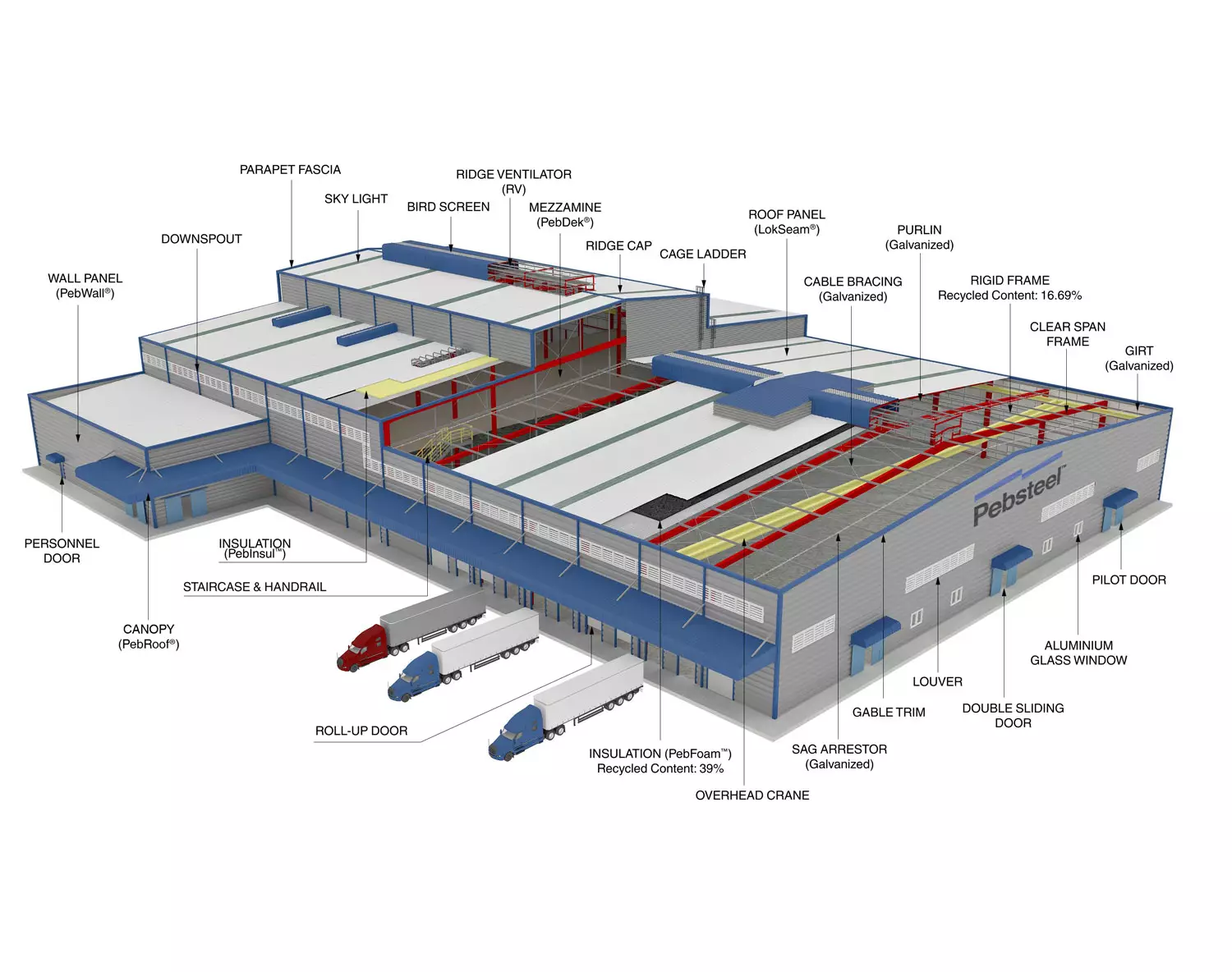

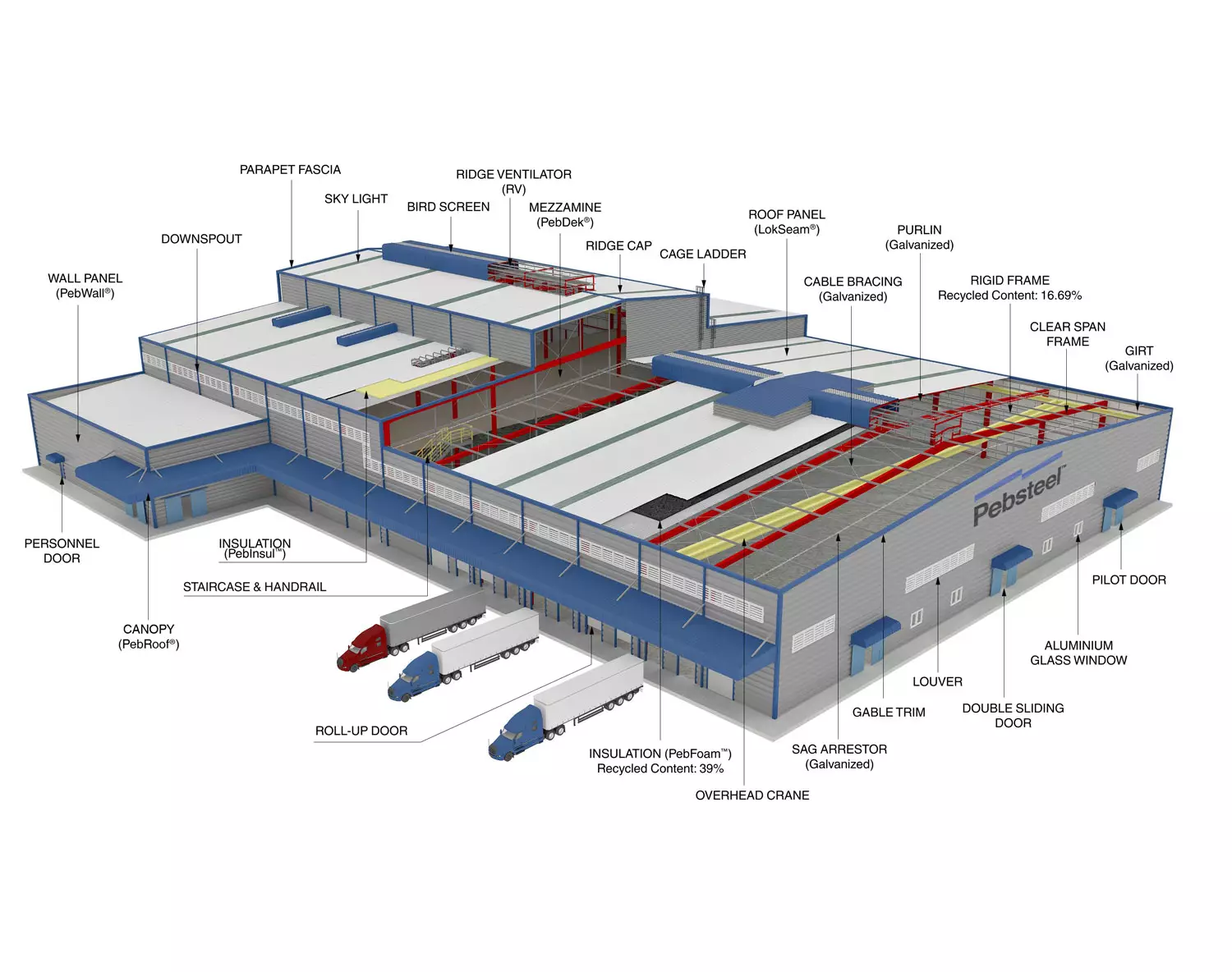

Pre-engineered metal buildings are constructed using prefabricated steel components, which are manufactured to precise specifications and then assembled on-site. These structures are engineered to meet specific requirements, such as load-bearing capacity, environmental conditions, and architectural design.

Key Benefits of Pre-Engineered Metal Buildings

1. Cost-Effective Solutions

PEMBs reduce costs in several ways:

• Lower material waste

• Reduced on-site labour

• Faster construction times

This makes them a budget-friendly option for businesses and organisations looking to save on construction expenses.

2. Durability and Strength

Metal buildings are highly durable and resistant to environmental factors such as wind, rain, and snow. They are also fire-resistant, making them a safe and long-lasting choice for various applications.

3. Quick Installation

Prefabrication ensures that components arrive ready for assembly, significantly reducing construction time compared to traditional methods. This is especially beneficial for projects with tight deadlines.

4. Versatility in Design

Pre-engineered metal buildings can be customised to suit diverse needs, including industrial, commercial, and agricultural applications. They can also be modified or expanded easily to accommodate future growth.

5. Sustainability

Metal buildings are environmentally friendly as steel is 100% recyclable. Additionally, these structures often feature energy-efficient designs, such as insulated panels and reflective roofing materials.

Popular Applications of Pre-Engineered Metal Buildings

1. Industrial Facilities

PEMBs are commonly used for factories, workshops, and manufacturing plants due to their ability to handle heavy machinery and equipment.

2. Warehouses

Their large clear spans and customisable layouts make metal buildings perfect for storage and distribution centres.

3. Commercial Buildings

Retail spaces, office complexes, and showrooms benefit from the cost-efficiency and aesthetic flexibility of metal buildings.

4. Agricultural Structures

Farmers use PEMBs for barns, grain storage, and livestock shelters, appreciating their durability and low maintenance.

5. Recreational and Community Facilities

From gymnasiums to sports arenas, PEMBs provide spacious and robust solutions for recreational spaces.

How to Choose the Right Pre-Engineered Metal Building

1. Define Your Requirements

Clearly outline the purpose, size, and design features of your building. Consider factors like load capacity, climate conditions, and future expansion needs.

2. Research Manufacturers

Look for reputable pre-engineered metal building manufacturers with proven experience and positive customer reviews. Ensure they comply with industry standards and offer customisation options.

3. Compare Costs

Request quotes from multiple manufacturers and compare prices, timelines, and additional services, such as installation or after-sales support.

4. Check Certifications

Verify that the manufacturer adheres to international quality standards, such as ISO certifications, to ensure the durability and safety of your building.

5. Evaluate Customisation Options

Choose a provider that offers flexible design solutions, such as varying roof types, wall panels, and interior layouts, to meet your specific needs.

Steps in the PEMB Construction Process

1. Initial Consultation

Discuss your project requirements with the manufacturer, including the building’s purpose, dimensions, and budget.

2. Design and Engineering

The manufacturer creates a customised design that considers local building codes, environmental factors, and functional needs.

3. Fabrication

Steel components are manufactured in a controlled factory environment, ensuring precision and quality.

4. Delivery and Assembly

The prefabricated components are delivered to the site and assembled quickly using specialised equipment.

5. Inspection and Finalisation

The completed structure is inspected to ensure it meets all safety and quality standards.

Advantages Over Traditional Construction

1. Faster Construction Time

Pre-engineered metal buildings can be assembled in weeks, while traditional construction may take months or even years.

2. Lower Costs

Material efficiency and reduced labour requirements make PEMBs a more affordable option.

3. Flexibility

PEMBs offer design versatility and are easier to modify or expand compared to traditional buildings.

4. Sustainability

The use of recyclable materials and energy-efficient designs makes PEMBs a greener choice.

Frequently Asked Questions

Q: Are pre-engineered metal buildings suitable for all climates?

Yes, PEMBs can be designed to withstand extreme weather conditions, including heavy snow, high winds, and earthquakes.

Q: Can I customise the interior of a pre-engineered metal building?

Absolutely. Interior layouts, partitions, and finishes can be tailored to meet your specific needs.

Q: How long do PEMBs last?

With proper maintenance, pre-engineered metal buildings can last several decades, making them a reliable long-term investment.

Pre-engineered metal buildings are a game-changer in the construction industry, offering unparalleled benefits such as cost efficiency, durability, and customisation. Whether you’re planning an industrial facility, commercial space, or agricultural structure, PEMBs provide a sustainable and practical solution.

By partnering with a reputable manufacturer and carefully planning your project, you can enjoy the full advantages of a pre-engineered metal building. Start exploring your options today to find the perfect solution for your construction needs.